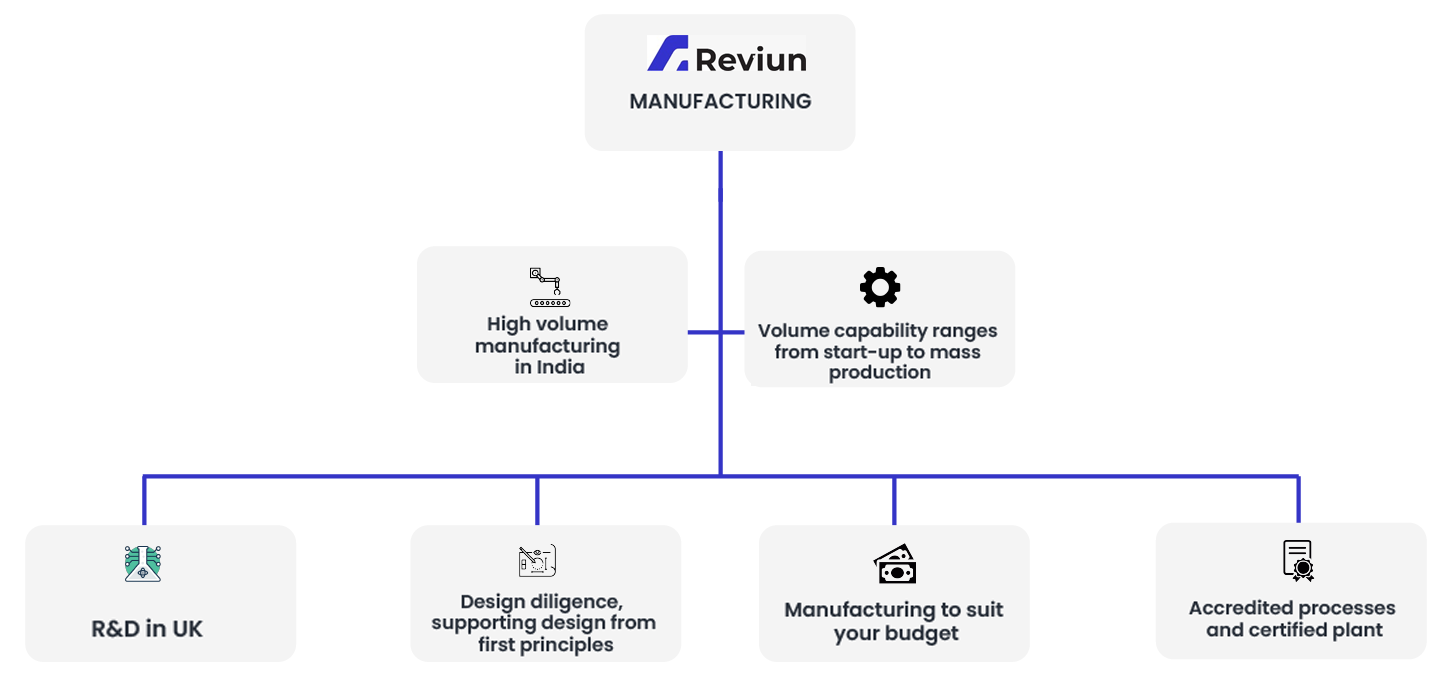

Manufacturing & Instrumentation

Why Reviun??? From prototype to production...

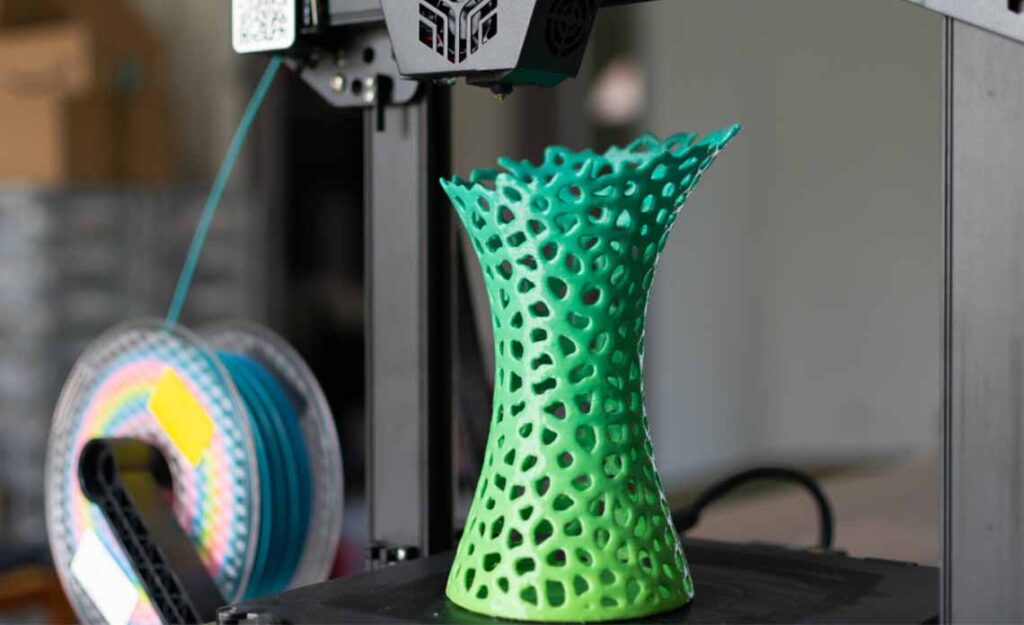

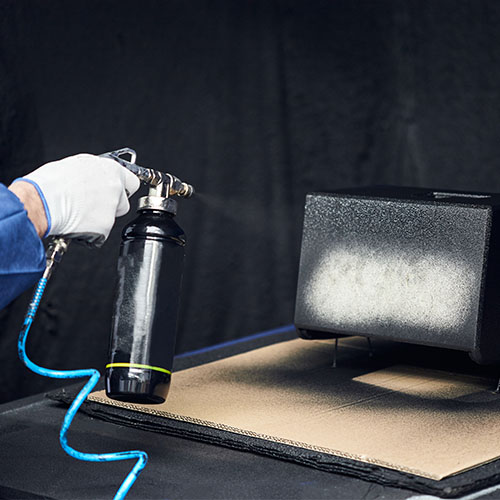

Additive manufacturing, also known as 3D printing, is a process of creating a physical object by depositing successive layers of material, according to a digital model. It is a versatile and rapidly evolving technology that is used in a wide range of industries, including aerospace, automotive, medical, and consumer products. Our additive manufacturing services are designed to help customers improve the efficiency and flexibility of their operations. We offer a range of additive manufacturing services, including the design and development of custom prototypes, small batch production, and one-off custom products. Our team has expertise in a variety of fields, including mechanical engineering, industrial design, and materials science, which enables us to tackle complex design challenges and deliver high-quality solutions.

We say that additive manufacturing services refer to the process of designing and creating physical objects using digital manufacturing technology. These services can be provided by us and we are specialised in 3D printing, and can customize your idea to fine detail to meet the specific needs and requirements of our client’s project.

Our additive manufacturing services typically involve a these steps, including:

This involves creating a digital model of the object using computer-aided design (CAD) software.

This involves choosing the appropriate material for the object, based on the desired properties and performance characteristics.

This involves using a 3D printer to create the object by depositing successive layers of material according to the digital model. .

This involves post-processing the object to remove excess material, smooth rough edges, or add other desired features.

Overall, we offer additive manufacturing services for a wide range of benefits, including the ability to create complex and customized objects, short lead times, and reduced material waste. They are an increasingly popular choice for companies looking to create prototypes, small batch production, or one-off custom products. We are happy to offer consulting and support services to help our customers get the most out of their 3D printed objects.

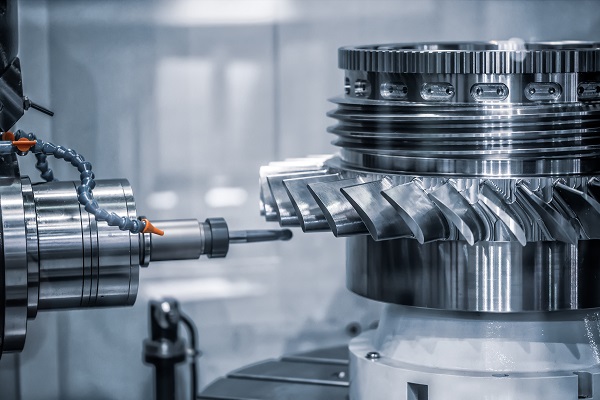

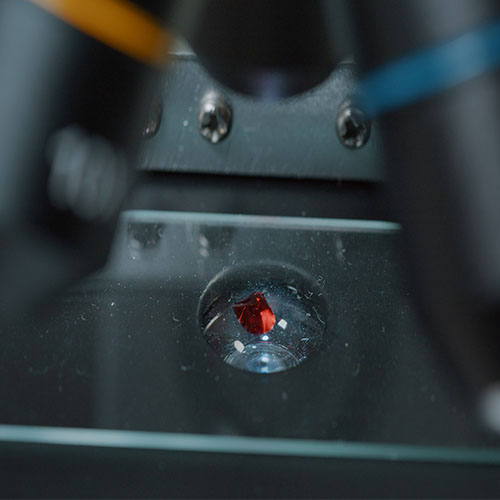

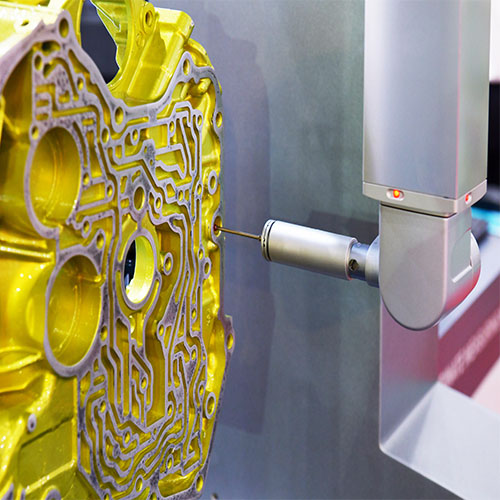

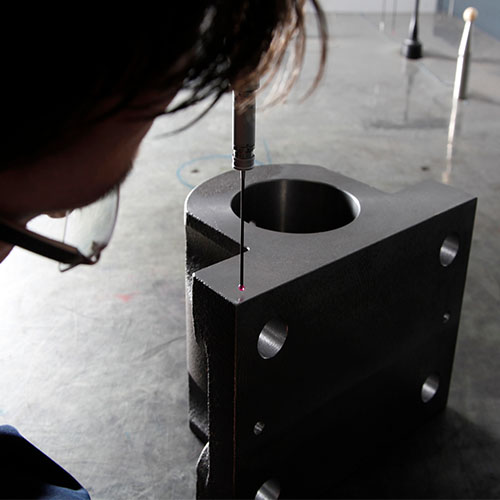

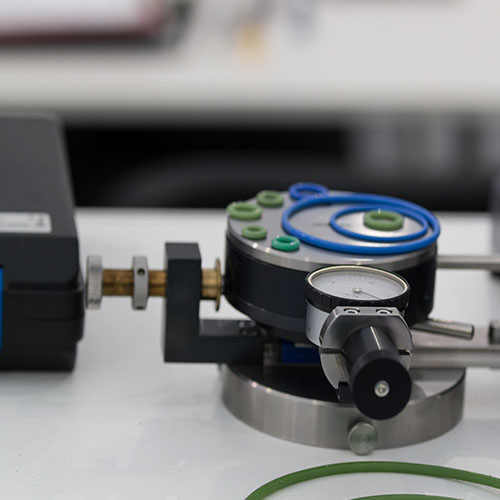

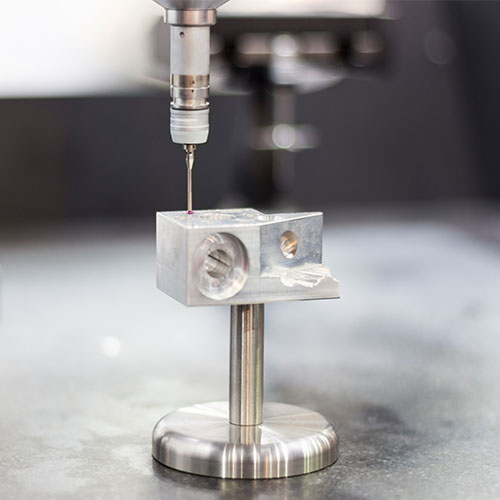

We Provide Precision Measurement Services Using Advanced CMM (Coordinate Measuring Machine) Technology, Including Optical 2D And 3D Measurement Systems. Our Team Of Experienced Professionals Is Dedicated To Providing Accurate And Reliable Measurement Solutions For A Wide Range Of Machine Parts And Components. At Our Facility, We Use State-Of-The-Art CMM Machines And Optical Measurement Equipment To Ensure That Your Parts Are Measured With The Utmost Precision And Accuracy. Our CMM Machines Are Capable Of Measuring Parts With A High Degree Of Accuracy, Allowing Us To Provide Detailed Analysis Of Even The Most Complex Geometries.

Our Team Of Experts Can Work With You To Develop A Custom Measurement Solution That Meets Your Specific Needs. We Can Provide Accurate And Reliable Measurement Data For Quality Control, Product Development, And Process Improvement. If You're Looking For Precision Measurement Services Using Advanced CMM Technology, Including Optical 2D And 3D Measurement Systems, You've Come To The Right Place. Contact Us Today To Learn More About Our Services And How We Can Help You With Your Measurement Needs.

At Revaron, We Take A Collaborative Approach To Our Work, Engaging With You To Understand Your Requirements And Goals For Your Project. We Use Our Expertise And Industry Knowledge To Provide You With Innovative Ideas, And Work With You Through Every Step Of The Design Process, From Concept To Manufacturing. We Specialize In A Range Of Industries, Including Aerospace, Automotive, Consumer Products, And Medical Devices. No Matter The Industry, Our Commitment To Quality And Attention To Detail Is Unwavering.

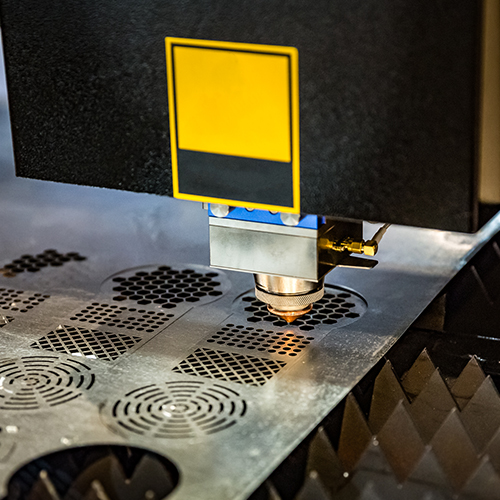

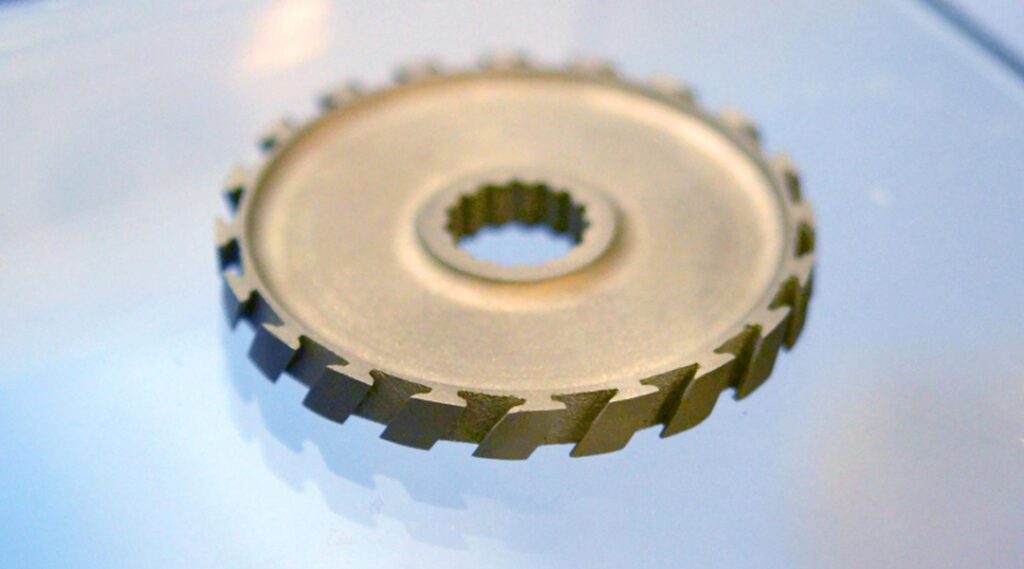

Our State-Of-The-Art Laser Cutting Technology Provides High-Quality, Efficient, And Cost-Effective Sheet Metal Cutting Solutions For Various Industries. Our Laser Cutting Service Is Used To Create Complex Shapes And Designs That Are Difficult Or Impossible To Achieve With Traditional Cutting Methods. Laser Cutting Can Be Used To Cut A Variety Of Metals And Alloys Ideal For Producing Parts And Components With Tight Tolerances And Intricate Details.

Metals and Alloys: Mild steel, Stainless steel, Aluminum, Copper, and Brass.

Maximum cutting size of sheet: 3000mm x 1500mm

Maximum sheet thickness: 16mm (Mild steel plate),10 mm (stainless steel), 8mm (aluminium),4mm (copper), 6mm (brass and other alloys)

Our facilities are equipped with cutting edge tools which produces complex and intricate shapes with a high degree of accuracy.

We Use Computer-Controlled Machines To Bend And Form Metal Sheets Into Precise Shapes And Angles. This Process Is Ideal For Producing Complex And Intricate Designs With High Accuracy And Repeatability. Our Machines Can Bend Metal Sheets Of Varying Thicknesses And Lengths, Making Them Suitable For A Wide Range Of Applications.

Our Welding Services Are Used In Sheet Metal Manufacturing To Create A Wide Range Of Products And Components, Including Structural Frames, Enclosures, Brackets, And Housings. We Provide Welding Services Be Join Metal Sheets Of Varying Thicknesses And Materials, And It Is Ideal For Creating Strong And Durable Products That Can Withstand The Stresses And Strains Of Heavy Use.

We Have A Well-Equipped Team, Resources And Assembly Skills To Cater Our Customers'

Requirements For Short-, Medium- And Long-Term Projects.

We Can Integrate Fixings Such As Rivets, Nut-Inserts, Hinges, Nuts And Bolts In The

Manufacturing Process. Our Longstanding Affiliations With A Broad Range Of Suppliers

Allow Us To Provide A Complete Solution For Our Customers That Incorporate Machining,

Electroplating And Powder Coating Services In Addition To Our Own Services.

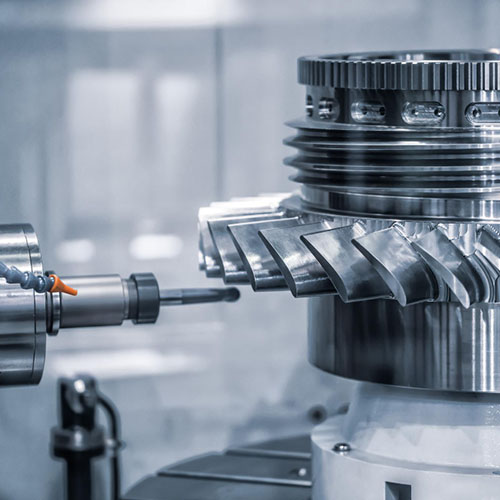

Components For The Automotive And Aerospace Industries

Electrical Enclosures And Panels

Decorative And Architectural Features

Medical And Scientific Instruments

Medical And Scientific Instruments

Parts For Industrial Machinery And Equipment

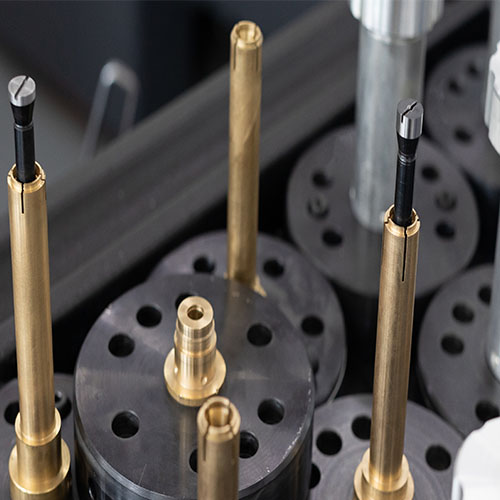

We Pride Ourselves On Delivering The Highest Quality Products And Services. Our Quality Control Processes Ensure That Every Part We Produce Meets The Highest Standards Of Accuracy And Consistency. We Use A Range Of Inspection Equipment, Including CMMs, Tool Setters, Height Gauges, And Micrometers, To Ensure That Our Products Meet Or Exceed Your Expectations.

We Also Offer Value-Added Services, Including Finishing, Assembly, And Packaging. Our Finishing Services Include Powder Coating, Anodising, And Plating. We Can Also Provide Assembly Services To Deliver Completed Products Directly To Your Production Line.

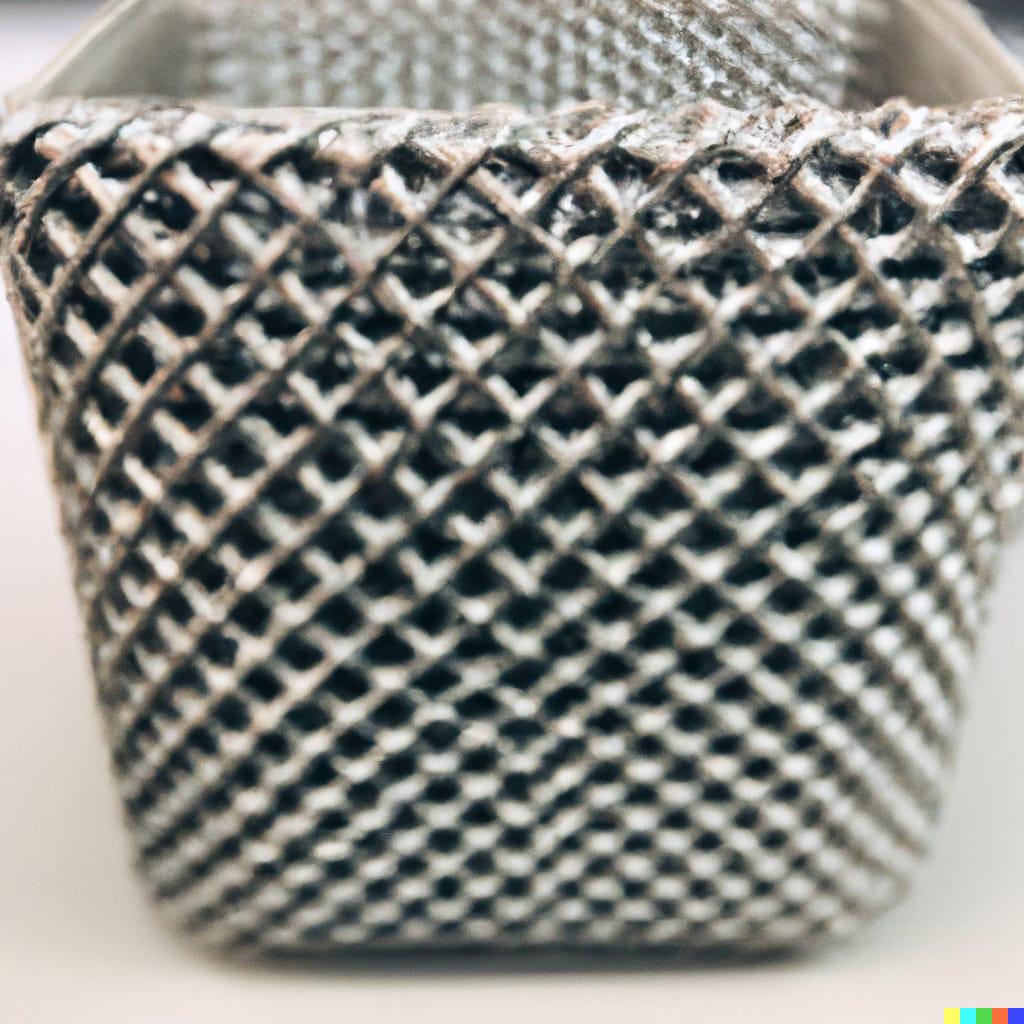

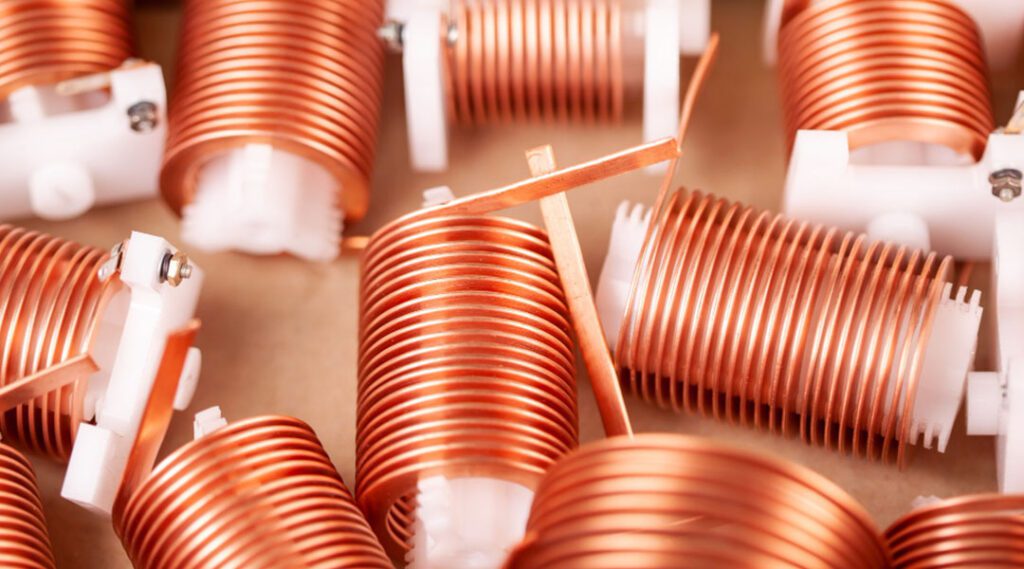

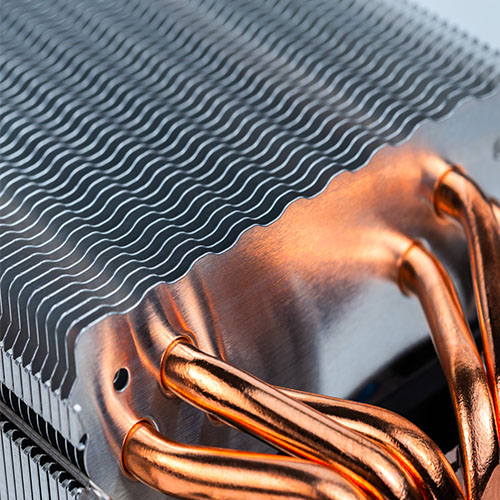

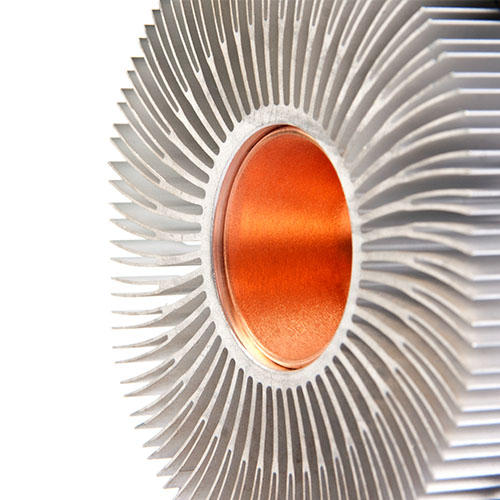

Our Thermal Management Services Involve The Design, Production, And Testing Of Components Such As Heat Sinks, Heat Pipes, Cooling Fans, And Liquid Cooling Systems. Our Heat Sinks Are Used To Absorb And Dissipate Heat Generated By Any Power Devices, While Cooling Fans And Liquid Cooling Systems Are Used To Actively Remove Heat From The Device And Transfer It To A Heat Sink. In Addition To Electronic Devices, Our Thermal Management Components Are Also Used In Other Industries, Including Automotive, Aerospace, And Power Generation. For Example, We Have Recently Developed Heat Exchangers For EV Vehicles To Transfer Heat From The Engine To The Cooling System And Additionally Generate Power.

We Use Advanced Thermal Analysis Software To Simulate And Optimize The Performance Of Our Components, Ensuring That They Meet Or Exceed Our Clients' Expectations. We Also Conduct Rigorous Testing To Ensure That Our Components Are Reliable And Durable, Even Under Extreme Conditions.

Engineering Design Consultants

Thermal Design, Welding, Heat pipes, design consulting (recuperator, motor design)

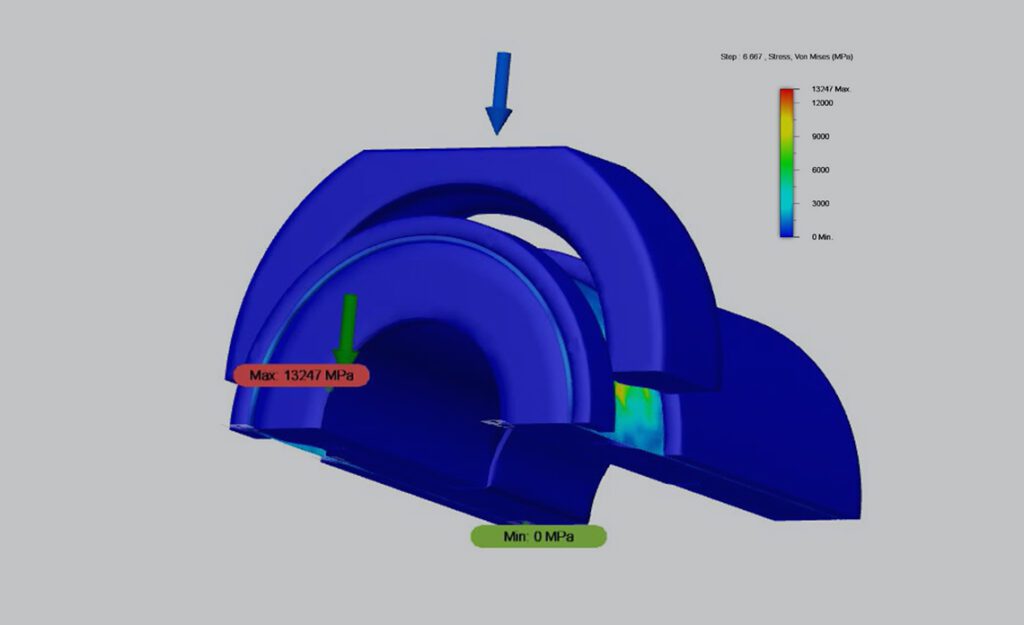

Our Design And Consultancy Services Include CAD, CAM, FDM, And FEA. Our Team Of Experienced Designers And Engineers Provide High-Quality Solutions To Meet Your Needs.

Computer-Aided Design Is A Powerful Tool That Allows Us To Create Detailed 2D And 3D Models Of Your Designs. Our CAD Services Enable Us To Take Your Idea And Turn It Into A Virtual Prototype That Can Be Viewed And Modified Before Moving To The Production Stage.

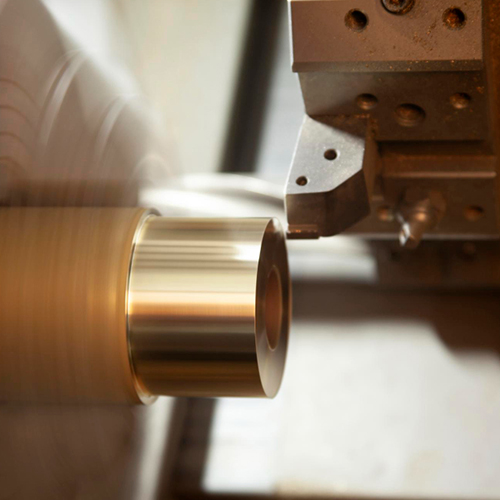

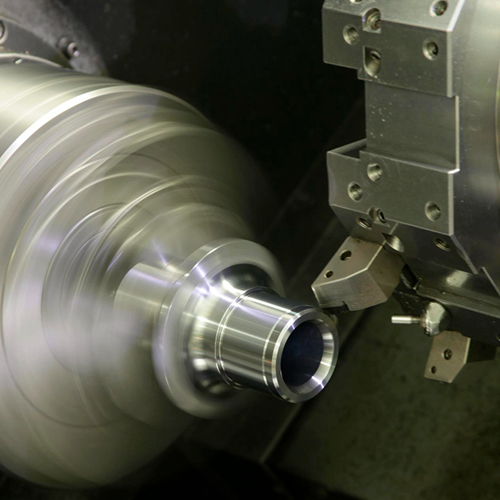

Computer-Aided Manufacturing Is The Next Step In The Process. Our CAM Services Allow Us To Use The CAD Models To Generate Toolpaths For CNC Machines To Create The Final Product. This Process Ensures Precision And Consistency In The Manufacturing Process.

Fused Deposition Modeling Is A 3D Printing Technology That Produces Functional Prototypes And End-Use Parts With Great Accuracy. Our FDM Services Utilize The Latest Technology To Create Durable And High-Quality Parts.

Finite Element Analysis Is A Simulation Tool That Allows Us To Test The Strength And Durability Of Your Product In A Virtual Environment. By Analyzing The Stresses And Strains On Your Design, We Can Identify Potential Issues And Optimize Your Product Before Moving To The Production Stage.

We Specialize In Designing And Producing Top-Quality High Vacuum Products For A Variety Of Industries. Our Expertise In High Vacuum Technology Enables Us To Offer Custom Solutions For All Of Your Vacuum Product Needs. We Wish To Say That Our Strength Is Custom Design Of Vacuum Products For R&D Services. We Understand That Every Project Is Different, And We Pride Ourselves On Our Ability To Create Innovative Solutions That Meet Even The Most Challenging Requirements.

Our Products Are Subject To Rigorous Testing And Inspection To Ensure That They Meet Or Exceed Industry Standards. Our Quality Control Processes Include Vacuum Leak Testing, Surface Finish Analysis, And Dimensional Measurements To Ensure That Our Products Are Of The Highest Quality.

Our Focus Is Not Solely On Our Products, But Also On The Products That We Manufacture For You. Rest Assured, We Possess The Passion And Capabilities To Produce Anything From One Unit To One Hundred Thousand Units, Treating Both Prototypes And Mass Production With Equal Care And Attention To Detail.

We do 3D Printig services.